Technical Solution

Industrial Design & Engineering Development

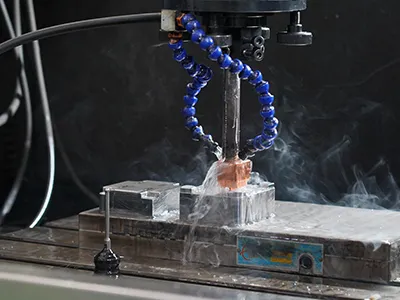

Precision Mold Technology Development

Formulation Science & Laboratory Research

Engineering Prototyping

Standardized Laboratory Testing

01Industrial Design & Engineering Development

02Precision Mold Technology Development

03Formulation Science & Laboratory Research

04Engineering Prototyping

05Standardized Laboratory Testing

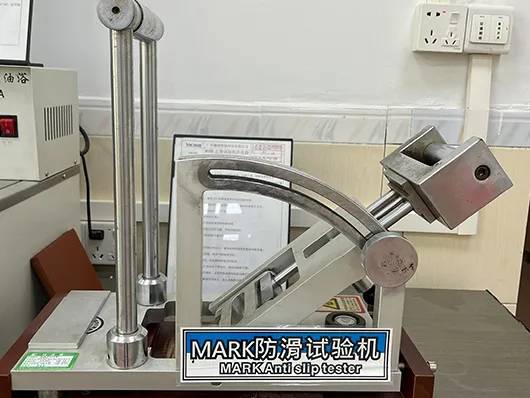

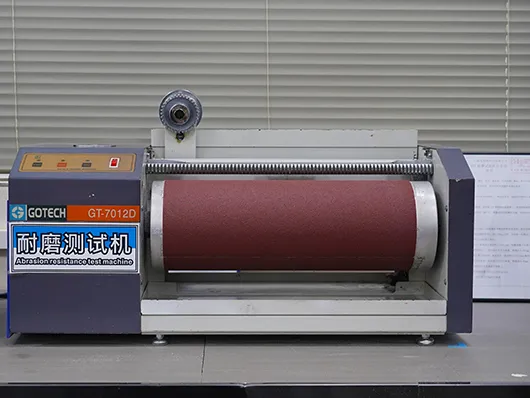

Lab Testing Machines

Quadruple Testing Protocol: Physical-Accelerated-Data-AI Release

Rubber Rheometer & Mooney Test Machine

MARK Anti Slip Tester

ITT Tire Inspection Equipment

Sunlight aging Machine & Hot aging testing Machine

Abrasion resistance Test Machine

Ozone aging testing machine & Constant temperature and humidity